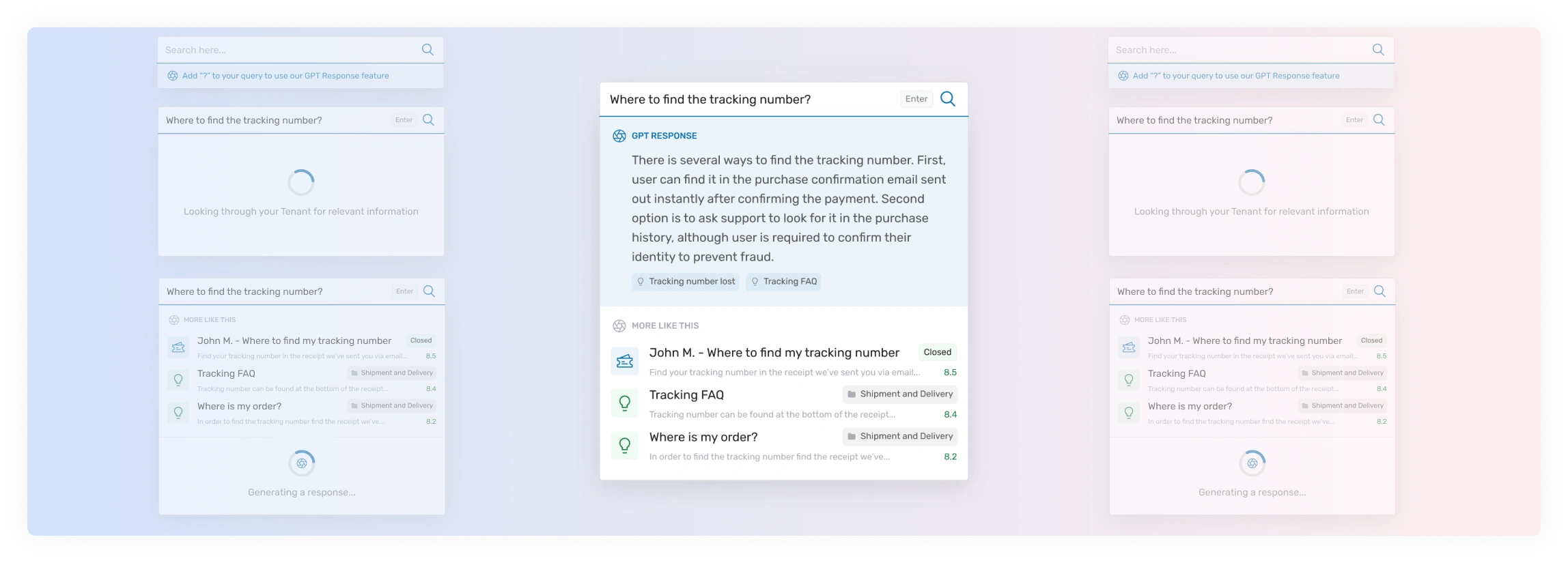

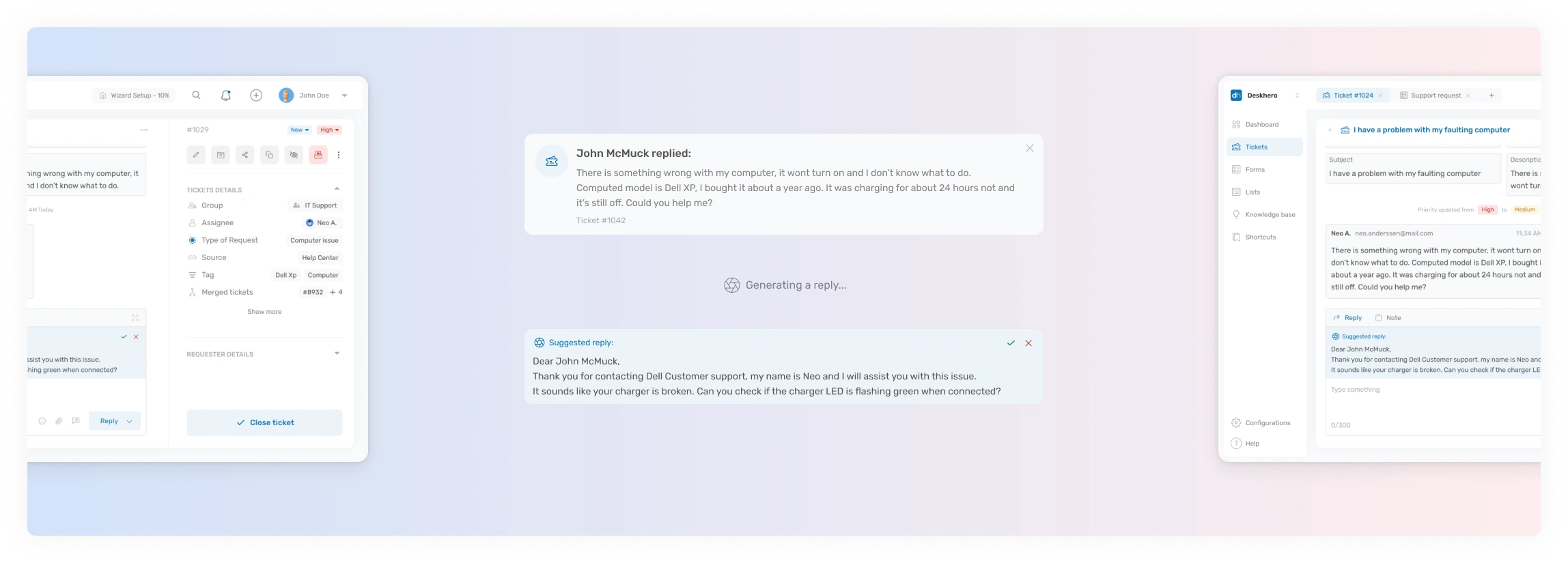

Companies in the manufacturing toilet rolls, napkins etc. business area can use the AI capability 'In app search' in Deskhero to quickly find relevant information within their data. By utilizing the search bar in the platform, they can enter their queries and receive comprehensive results that include traditional search methods and OpenAI Embeddings. This allows them to easily access data from tickets, knowledge base articles, scraped websites, and more. The AI capability ensures that the search results are accurate and can even generate human-like replies based on the relevant parts of the matched customer data.

Use case 1

Quality Control - Manufacturing companies can use the 'In app search' AI capability to quickly find information related to quality control processes. They can search for specific keywords or phrases to retrieve data on product specifications, testing procedures, and quality assurance guidelines. This enables them to ensure that their toilet rolls, napkins, and other products meet the required quality standards.

Use case 2

Inventory Management - Companies can utilize the 'In app search' feature to efficiently manage their inventory. They can search for stock levels, reorder points, and supplier information to streamline their procurement process. Additionally, they can retrieve data on production schedules, demand forecasts, and raw material availability to optimize their inventory management strategies.

Use case 3

Troubleshooting - In the event of production issues or equipment malfunctions, manufacturing companies can leverage the 'In app search' AI capability to troubleshoot problems. They can search for troubleshooting guides, maintenance procedures, and equipment manuals to quickly identify and resolve issues. This minimizes downtime and ensures smooth operations in the manufacturing process.